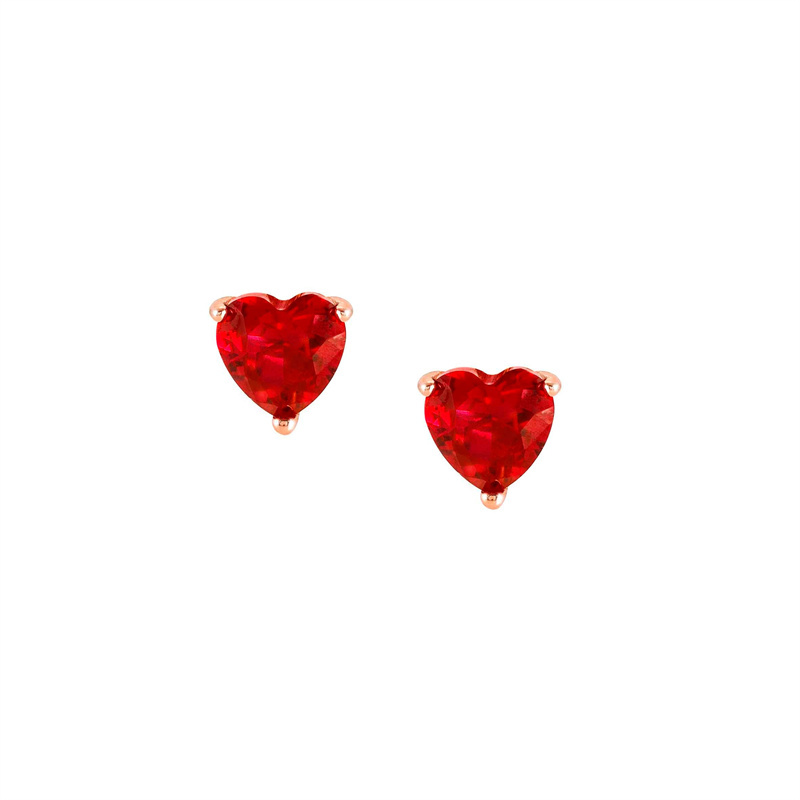

Russian Jewelry Company Bulk Custom Zirconia Stud Earrings

OEM/ODM jewelry manufacturer design custom your own jewelry

LET’S GET STARTED : mo@kingjy.com

Russian Jewelry Company Partners with JINGYING for Bulk Custom Zirconia Stud Earrings Production

Introduction

In the competitive world of jewelry manufacturing, partnerships between companies from different regions and backgrounds often result in the creation of exceptional products. One such successful collaboration is between a renowned Russian jewelry company and JINGYING, a well-established jewelry manufacturer. The partnership centers on the bulk production of custom-designed zirconia stud earrings, which highlights both companies’ commitment to quality, craftsmanship, and precision.

This article provides a detailed account of how JINGYING Company worked closely with a Russian client to create a large batch of zirconia stud earrings. From the initial design phase to the final delivery, this collaboration underscores the significant role of custom manufacturing in the global jewelry market. We will explore the steps involved in the process, the unique characteristics of zirconia as a material, the significance of the partnership, and the mutual benefits that both JINGYING and the Russian jewelry company have reaped.

JINGYING Company: A Leader in Custom Jewelry Manufacturing

Founded over 20 years ago, JINGYING Company has positioned itself as a leader in the jewelry manufacturing industry, known for its innovation and high-quality production. The company specializes in creating bespoke, handcrafted jewelry, including necklaces, rings, bracelets, earrings, and pendants, with a focus on using premium materials and cutting-edge technology.

JINGYING’s extensive expertise in the custom jewelry field has allowed them to work with numerous clients from around the world. Their capabilities include designing and manufacturing jewelry that meets the specific demands of individual customers, ranging from luxury designers to mass-market retailers. This versatility and dedication to quality have made JINGYING a trusted name in the industry.

One of the key reasons why JINGYING stands out in the competitive jewelry market is their ability to blend traditional craftsmanship with modern technology. The company uses advanced tools such as CAD (computer-aided design) software, 3D printing, and precision laser cutting to ensure that every piece of jewelry is both aesthetically pleasing and precise in its construction.

The Russian Jewelry Company: Focus on Quality and Precision

The Russian jewelry company, which has been in the market for several decades, is known for offering high-end, luxurious jewelry. The company has carved out a niche in producing exquisite, one-of-a-kind pieces that appeal to both traditional and contemporary tastes. The Russian company specializes in both precious metal jewelry and cubic zirconia (CZ) jewelry, which offers a more affordable alternative to diamonds without compromising on appearance.

The company’s clientele includes upscale boutiques, individual collectors, and international retailers looking for premium, custom-made pieces. By combining traditional Russian jewelry-making techniques with innovative design practices, the company has built a strong reputation both domestically and internationally.

To keep up with increasing demand, the Russian jewelry company decided to partner with JINGYING for the production of custom-made zirconia stud earrings. The company sought a reliable and experienced partner who could meet their high standards in terms of material quality, craftsmanship, and timely delivery, making JINGYING the ideal choice.

The Demand for Zirconia: A Popular and Versatile Alternative

Cubic zirconia (CZ) is a synthetic gemstone that has become an increasingly popular alternative to diamonds in the jewelry industry. Known for its brilliance and affordability, CZ offers a similar appearance to diamonds but at a fraction of the cost. This makes it an attractive choice for both consumers and manufacturers alike.

For the Russian jewelry company, zirconia stud earrings represented an opportunity to create high-quality, affordable luxury jewelry. The company aimed to produce a large batch of zirconia stud earrings that would appeal to customers looking for elegant yet reasonably priced pieces. Zirconia is particularly well-suited for stud earrings because of its sparkle, durability, and ability to mimic the appearance of diamonds, making it the perfect choice for this particular product line.

JINGYING’s expertise in working with zirconia and other gemstones made them a natural choice for the production of these earrings. The company’s ability to create detailed and intricate designs while maintaining the highest standards of quality control was a significant factor in the Russian jewelry company’s decision to partner with JINGYING.

The Customization Process: From Concept to Creation

Creating custom jewelry is a multifaceted process that requires close collaboration between the manufacturer and the client. For the production of zirconia stud earrings, JINGYING worked closely with the Russian jewelry company to ensure that every detail was perfect. Here’s a closer look at the key steps involved in the customization process.

Step 1: Design Collaboration

The first step in the process was the design phase, where the Russian client provided JINGYING with their ideas for the zirconia stud earrings. The client specified the desired style, size, and overall aesthetic of the earrings. The design was to be both classic and contemporary, with a focus on simplicity and elegance.

JINGYING’s design team worked closely with the Russian client to create a range of digital renderings and sketches. These initial designs were shared with the client for feedback and refinement. Several iterations were made to ensure that the earrings would meet the client’s expectations in terms of both style and quality.

Step 2: Material Selection

Once the design was finalized, the next step involved selecting the materials. The client requested that the earrings feature high-quality cubic zirconia stones, which would be set in a setting of sterling silver or 14k gold. JINGYING’s procurement team sourced the finest CZ stones that matched the client’s specifications for clarity, cut, and size.

The Russian company also requested that the setting be durable and secure, ensuring that the zirconia stones would remain firmly in place even after prolonged use. JINGYING’s team used a combination of traditional prong settings and innovative techniques to ensure that the stones were securely set while still allowing for maximum light reflection.

Step 3: Prototyping

Before moving to full-scale production, JINGYING created prototypes of the zirconia stud earrings. The prototypes allowed the Russian client to evaluate the overall design, size, and comfort of the earrings. This stage also allowed for any necessary adjustments in terms of the earring’s dimensions or clasp mechanism.

After the prototypes were approved by the client, the final production process could begin.

Step 4: Manufacturing and Crafting

With the designs finalized and the materials in place, JINGYING’s skilled artisans began the production process. The earrings were crafted using a combination of machine and handcrafting techniques. The sterling silver or 14k gold settings were cast and shaped with precision, and the zirconia stones were carefully set in place.

JINGYING’s use of CAD technology allowed for precise measurements and ensured that every stone was perfectly aligned, giving the earrings their brilliant sparkle. The use of advanced equipment, such as laser engraving and 3D printing, allowed JINGYING to create intricate details in the earring design.

Each earring was then polished to a high shine, ensuring that the finished product was both visually appealing and smooth to the touch. The final earrings were checked for consistency, durability, and overall quality.

Quality Control: Ensuring Excellence

Quality control is an essential part of JINGYING’s production process. Each batch of zirconia stud earrings underwent a rigorous quality control process to ensure that the earrings met the highest standards of craftsmanship and quality. This process involved several key steps:

-

Stone Inspection: Each cubic zirconia stone was inspected for clarity, cut, and quality. Only stones that met the client’s specifications were used in the production process.

-

Setting Quality: The prong settings were carefully checked to ensure that the stones were securely placed and did not have any sharp edges.

-

Metalwork: The metal settings were inspected for smoothness, evenness, and durability. Any imperfections in the metalwork were addressed before proceeding to the next step.

-

Final Polish: The earrings were polished to perfection, ensuring that they had a brilliant, reflective surface and smooth edges.

JINGYING’s quality control team worked closely with the production team to identify any potential issues early in the process, ensuring that only flawless earrings made it to the final stage.

Logistics and Delivery: Timely Shipping

Given the large scale of the order, logistics and timely delivery were essential considerations for both JINGYING and the Russian client. JINGYING worked closely with reliable logistics partners to ensure that the earrings were packaged securely and delivered on time.

Each pair of earrings was carefully packaged to prevent any damage during transit, and the client was given regular updates on the status of the shipment. The logistics team ensured that the earrings were delivered safely and on schedule, meeting the client’s needs.

Mutual Benefits of the Partnership

The collaboration between JINGYING and the Russian jewelry company was mutually beneficial for both parties. For JINGYING, the order represented an opportunity to showcase their expertise in the production of high-quality zirconia jewelry. The company was able to demonstrate its ability to handle large-scale orders while maintaining precision and attention to detail.

For the Russian jewelry company, the partnership allowed them to offer their customers a new line of high-quality zirconia stud earrings that combined elegance, affordability, and durability. The earrings have proven to be a popular addition to their product range, helping to strengthen the brand’s reputation in the competitive jewelry market.

Conclusion

The successful collaboration between JINGYING and the Russian jewelry company for the production of zirconia stud earrings highlights the importance of custom manufacturing in the global jewelry industry. By combining creativity, expertise, and attention to detail, both companies have created a product that appeals to a broad customer base while maintaining the highest standards of quality.

As JINGYING continues to expand its international reach, partnerships like the one with the Russian jewelry company will be instrumental in driving the company’s growth and success. The ability to deliver custom, high-quality jewelry at scale is what sets JINGYING apart in the competitive jewelry manufacturing market.