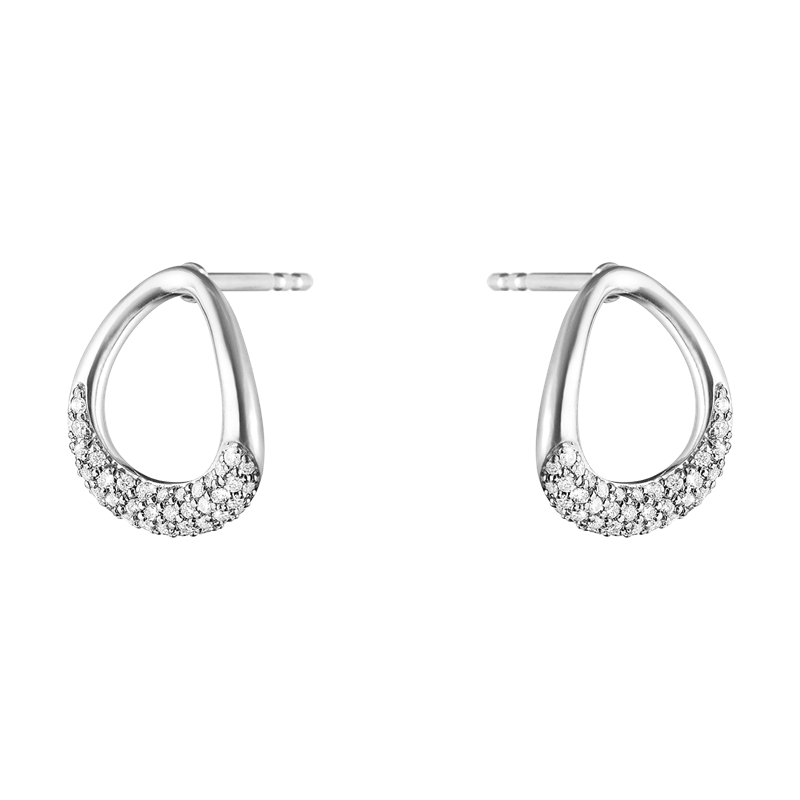

Belgian Custom Wholesale Fashion Jewelry 925 Silver Zircon Earrings

OEM/ODM jewelry manufacturer design custom your own jewelry

LET’S GET STARTED : mo@kingjy.com

The Synergy of Craftsmanship and Demand: Belgian Customers and JINGYING Revolutionize Fashion Jewelry with Mass-Produced Zircon Earrings

Introduction: The Rise of Zircon in Fashion Jewelry

In an era where affordability meets aspiration, fashion jewelry has undergone a seismic shift. Consumers increasingly seek pieces that mirror the elegance of precious gemstones without the exorbitant price tag. Enter cubic zirconia (CZ), a lab-created crystal renowned for its diamond-like brilliance and versatility. Among the vanguards of this revolution is JINGYING, a Chinese manufacturing powerhouse, whose collaboration with Belgian customers has set new benchmarks in the mass production of zircon earrings. This article explores how this partnership is reshaping trends, economies, and sustainability in the global jewelry industry.

Section 1: JINGYING – A Leader in Zircon Jewelry Manufacturing

Founded in 2005, JINGYING has carved a niche as a global leader in synthetic gemstone jewelry. Headquartered in Guangdong, China’s jewelry manufacturing hub, the company specializes in precision-cutting cubic zirconia and crafting them into high-fashion accessories.

- Technological Edge: JINGYING employs state-of-the-art CAD/CAM systems for design and automated laser-cutting machines, ensuring consistency across thousands of units.

- Scalability: With a production capacity exceeding 500,000 pieces monthly, JINGYING caters to bulk orders without compromising on turnaround times.

- Customization: Clients can choose from 50+ zircon shades, multiple metal finishes (e.g., gold-plated, rhodium), and settings (prong, bezel, halo).

This blend of innovation and flexibility has attracted clients from Europe, notably Belgium, where discerning jewelers demand both quality and volume.

Section 2: The Belgian Jewelry Market – Tradition Meets Modernity

Belgium, particularly Antwerp, is synonymous with diamonds. However, rising consumer demand for accessible luxury has pushed local retailers to explore alternatives.

- Market Shifts: Post-pandemic, 68% of Belgian consumers prioritized “affordable indulgence” in fashion accessories (EuroStat, 2023).

- Design Trends: Minimalist studs, chandelier earrings, and geometric designs dominate preferences, aligning with zircon’s adaptability.

- Ethical Considerations: Younger buyers favor eco-conscious brands, prompting Belgian jewelers to seek partners with sustainable practices.

Belgian companies, while steeped in tradition, turned to JINGYING to bridge the gap between heritage and contemporary demand.

Section 3: The Partnership – Why Belgian Firms Chose JINGYING

In 2021, Antwerp-based Luxe Éclat partnered with JINGYING to launch a zircon earring line. The collaboration’s success spurred similar deals with 15+ Belgian retailers. Key drivers include:

- Cost Efficiency: JINGYING’s zircon earrings cost 90% less than diamond equivalents, allowing Belgian firms to price competitively.

- Quality Assurance: Each stone undergoes rigorous checks for clarity, cut, and color consistency, meeting EU regulatory standards.

- Speed-to-Market: JINGYING’s 30-day production cycle (from design to shipping) enables rapid response to trend shifts.

“JINGYING understands our need for precision and scalability,” remarked Sophie De Vries, Luxe Éclat’s CEO. “They’ve become an extension of our brand.”

Section 4: Inside JINGYING’s Mass Production Process

Creating millions of identical zircon earrings requires a meticulously orchestrated workflow:

- Design Phase: Belgian clients submit sketches, which JINGYING’s team converts into 3D models using CAD software.

- Prototyping: A sample batch is produced for approval, often within 72 hours.

- Material Sourcing: Ethically sourced zirconia and hypoallergenic alloys are procured from certified suppliers.

- Automated Cutting: Lasers cut stones to precise dimensions (e.g., 1.5mm to 10mm), minimizing waste.

- Assembly: Robotic arms set stones into settings, inspected via AI-powered cameras.

- Quality Control: Each earring is tested for durability, luster, and clasp functionality.

This process ensures that even mass-produced items retain a handcrafted aesthetic.

Section 5: Sustainability – A Core Tenet of Collaboration

Belgian firms prioritize eco-responsibility, aligning with JINGYING’s green initiatives:

- Recycled Metals: 70% of earring bases use recycled silver or brass.

- Carbon-Neutral Goals: JINGYING’s solar-powered factories aim for zero emissions by 2025.

- Waste Reduction: Scrap metal and zirconia dust are repurposed into new products.

Such practices resonate with Belgium’s stringent environmental regulations and consumer expectations.

Section 6: Challenges and Innovations

The partnership hasn’t been without hurdles:

- Cultural Nuances: Early designs clashed with Belgian minimalism, requiring JINGYING to adapt its ornate Asian-inspired styles.

- Logistics: Shipping delays during the Suez Canal blockage (2021) prompted JINGYING to diversify transport routes, including rail via the China-Europe Railway Express.

Solutions like hiring European design consultants and blockchain-based tracking systems strengthened trust.

Section 7: Market Impact and Future Prospects

The Belgian-JINGYING synergy has rippled globally:

- Sales Growth: Luxe Éclat reported a 200% revenue increase from zircon lines in 2022.

- Trend Influence: “Antwerp Chic” – a blend of zirconia and recycled gold – is now emulated in Paris and New York.

Looking ahead, JINGYING plans to integrate augmented reality (AR) for virtual try-ons, further personalizing the consumer experience.

Conclusion: Redefining Global Jewelry Dynamics

The collaboration between Belgian customers and JINGYING underscores a transformative era where technology, sustainability, and cross-cultural exchange drive innovation. As zircon earrings adorn ears worldwide, this partnership exemplifies how traditional markets can evolve without sacrificing integrity—a lesson for industries beyond jewelry.